Is Your Site Truly Ready? A Checklist Before Your Container House Arrives

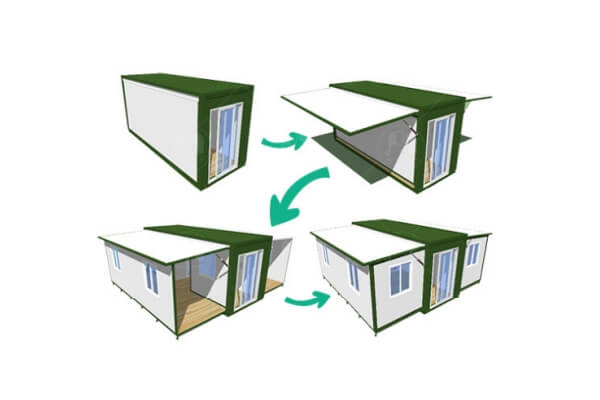

The “waiting period” after placing an order is actually crucial to the success of the entire project. While prefabricated container houses are synonymous with “plug and play,” customers must complete necessary preparations before the goods arrive to ensure a stable installation.

To ensure your house is perfectly in place, here are essential preparatory steps before delivery:

Site & Foundation: Building a Level Base

Although container houses don’t require deep foundations like traditional buildings, they cannot simply be placed anywhere on the ground. The flatness of a container house depends on the surface it is placed on. Placing the house directly on bare soil can lead to subsidence, moisture damage, and structural misalignment.

Leveling the Site: Ensure the installation area is flat, firm, and free of water accumulation.

Foundation Type Selection:

1. Concrete Pillar/Strip Foundation: The most common approach, using concrete supports at the four corners or under load-bearing beams.

2. Full Concrete Slab: For maximum stability, a single, hardened concrete slab can be laid.

3. Helical Ground Piles: Environmentally friendly and quick to install, suitable for areas with loose soil.

Leveling: This is the most important point. If the foundation is uneven, problems such as doors and windows not opening and closing properly, and compromised sealing may occur after the container house arrives.

Utility Connections: Bringing the House to Life

Before the house is built, you need to run all kinds of pipelines to the designated connection points.

Electricity Connection: Confirm that the specifications of the incoming power line meet the total power requirements of the house, and arrange for a professional electrician to install the external junction box.

Water Supply and Drainage System:

Water Inlet: Reserve water pipe interfaces and main valves.

Drainage: Determine the sewage discharge direction (municipal sewage pipe or septic tank). Ensure that the location of the drain outlet is perfectly aligned with the house design drawings.

Communication Network: If wired network is required, remember to lay fiber optic cables in advance.

Access and Lifting Conditions: Don’t let the “big guy” get stuck at intersections.

Prefabricated container houses are usually transported by large flatbed trucks; ensuring that they can be “brought in and unloaded” is crucial.

Road Survey: Check for height restrictions (e.g., trees, power lines), width restrictions, or sharp turns on roads leading to the destination.

Lifting Space: Sufficient hardened operating space must be provided for cranes to extend their booms, and there must be no overhead high-voltage lines causing interference.

Unloading Equipment Confirmation: Rent a crane of appropriate tonnage in advance, based on the weight of the container and the site distance.

Regulations and Approvals: Legality and compliance are prerequisites.

Don’t wait until the building is completed to discover it’s considered an illegal structure.

Land Access Permits: Confirm the land use designation and obtain temporary or permanent building permits from the local planning department.

Neighborhood Coordination: If the installation process involves road closures or noise, please inform your neighbors in advance.