How Is Prefabricated Construction Transforming the Future of Building?

The Future of Construction: Understanding Prefabricated Buildings

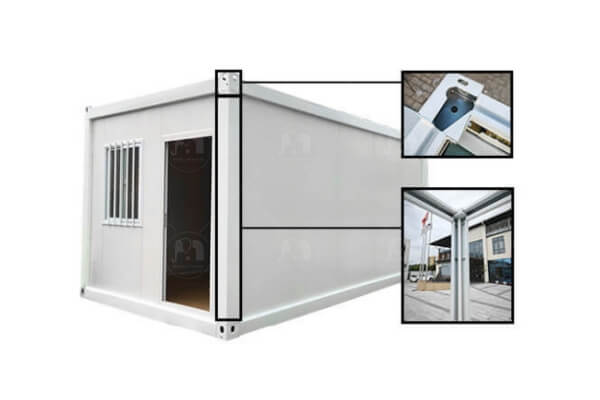

Prefabricated construction is revolutionizing the way we build. At its core, this method breaks down structures into standardized components—such as walls, floors, staircases, and kitchen/bathroom modules—manufactured in a controlled factory setting before being transported to the site for precise assembly.

As a key direction in industrialized construction, prefabricated buildings integrate standardized design, factory-based production, modular assembly, digital management, and intelligent applications to optimize the entire construction process. This approach shifts traditional wet construction methods to a modern factory environment, where automated production lines ensure efficiency and precision.

Key Advantages of Prefabricated Construction

1. Efficient and Time-Saving

Since factory production is unaffected by weather or site conditions, prefabricated components are manufactured with mechanical precision, reducing construction time by over 50% compared to conventional methods. This makes it particularly beneficial for camp facilities, emergency projects, and time-sensitive developments.

2. Eco-Friendly and Sustainable

By significantly minimizing on-site operations, prefabrication reduces construction waste by 80%, alongside lower dust and noise pollution. This makes it ideal for sensitive ecological zones and urban centers where environmental impact is a concern.

3. High-Quality and Durable

With stringent quality control during factory production, prefabricated components maintain millimeter-level accuracy, eliminating common issues such as uneven surfaces and misaligned joints seen in traditional construction. As a result, overall building durability and performance are greatly enhanced.

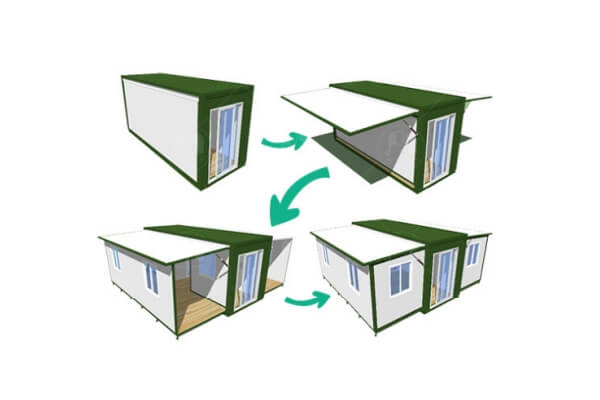

4. Flexible and Adaptable

Designed for modular combination, prefabricated structures accommodate diverse layouts and functional needs. Additionally, they can be easily dismantled and reassembled for future modifications—making them perfect for camps, temporary facilities, and evolving architectural demands.

5. Cost-Effective

Although initial investment in molds may be higher, mass production significantly reduces costs over time. With shorter construction schedules, lower material wastage, and reduced labor expenses, prefabricated buildings offer 20% lower overall costs compared to conventional construction methods, making them a financially viable long-term solution.

Real-World Applications

Prefabricated construction has already made a significant impact across various industries, from camp developments and commercial buildings to public infrastructure and emergency response projects. As technology continues to advance, this method provides an innovative, sustainable, and efficient solution for creating high-quality spaces with speed and precision.

The future of construction is here—modular, efficient, and smarter than ever.