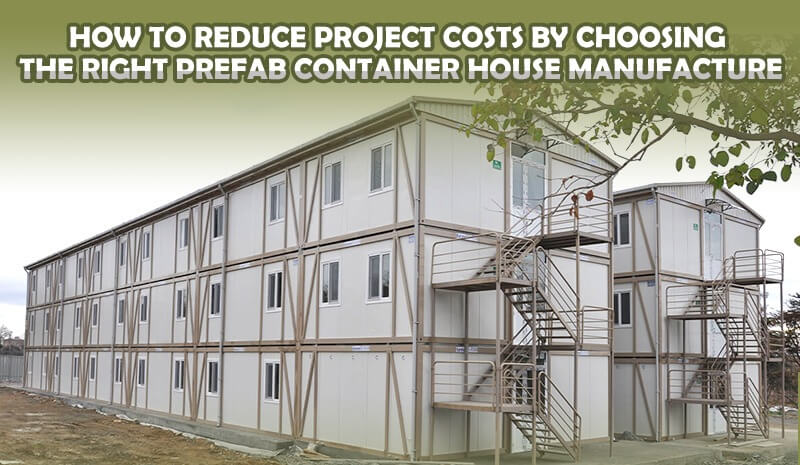

Cómo para Reducir Costes de Proyecto por Escoger el Derecho Prefab Fabricante de Casa del Envase?

Prefab container houses are favored in engineering construction, temporary office, and dormitory construction scenarios largely because they can significantly reduce overall project costs. However, truly achieving “saving money without sacrificing quality” hinges on choosing a manufacturer that can help you optimize costs. Purchasing a prefab container house isn’t simply about comparing prices, but rather about comparing the ability to control costs throughout the entire project lifecycle. Below, we outline the selection logic from a cost management perspective.

I. Materials and Structure Determine Long-Term Costs—Cheaper Isn’t Always Better

In prefab container houses, the quality of materials directly affects lifespan and subsequent maintenance costs.

Excellent manufacturers typically:

Use steel and high-density insulation panels that meet national standards

Employ anti-corrosion and rust-proofing treatments to reduce the frequency of later maintenance

Provide structural calculations to ensure long-term stability

Low-priced products often cut corners on panel thickness, steel strength, and anti-corrosion processes. While they may seem cheaper in the short term, long-term costs can double due to leaks, deformation, and frequent repairs.

True cost control lies in reducing future hidden expenses.

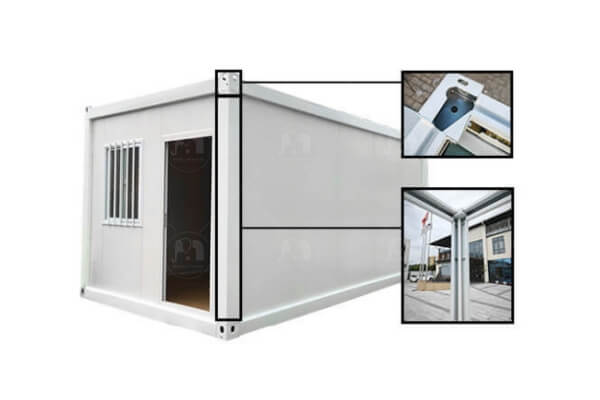

II. Standardized Production Reduces Labor Costs – Efficiency Equals Savings

The cost advantage of Prefab container houses stems from factory prefabrication.

When choosing a manufacturer, focus on their production capabilities:

Do they possess standardized, modular production lines?

Do they own their own factory instead of outsourcing?

Is their production process mature and controllable?

Higher standardization leads to smaller production errors, faster on-site installation, and lower labor costs.

Data shows that manufacturers using modular production can reduce average installation time by 30%–40%, directly reducing on-site construction costs.

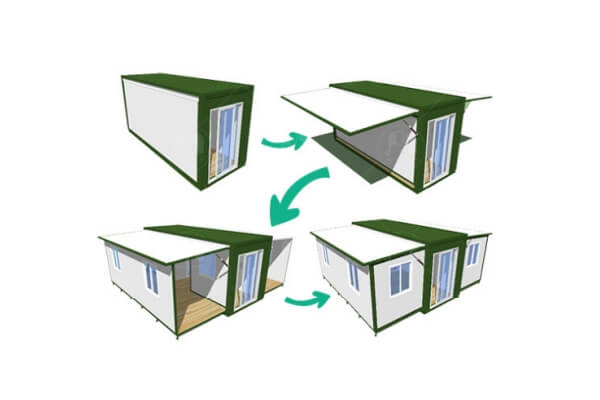

III. Customization Capabilities Affect Later Retrofit Costs – One-Time Design Saves the Most Money

Different project requirements necessitate different functional configurations for Prefab container houses.

If a manufacturer lacks customization capabilities, later retrofits often incur higher costs.

Excellent manufacturers will:

Plan water, electricity, air conditioning, and network interfaces in advance based on the usage scenario.

Provide multiple layout options to reduce later demolition and alterations.

Support the integration of functions such as restrooms, storage rooms, and meeting rooms.

One-time design avoids additional costs associated with rework.

In summary: Choosing a prefab container house is choosing a cost management solution.

From a cost control perspective, an excellent prefab container house manufacturer must possess the following:

High-quality materials, reducing maintenance costs

Standardized production, reducing labor costs

Strong customization capabilities, avoiding later modifications

Saving money is not about lowering prices, but about reducing total lifecycle costs.

Choosing the right manufacturer means saving a significant amount of hidden expenses for your project.